What is Six Sigma Quality and DIAMC?

Six Sigma is a quality measurement technique that can improve business processes.

Some industries use the term

Five Nines to indicate 99999% quality acceptance.

The

SMART Quality team developed six sigma metrics to measure the

quality

and usability of technical documentation.

The symbol

sigma (σ) represents

a quality measurement, from one sigma (low) to six sigma (high).

The acronym

DIAMC indicates five

processes,

Design,

Improve,

Analyze,

Measure

and

Control. The

writers use the

MAXit Checker to

control, correct and edit errors in software documentation.

For example, the cost of 1 hour of downtime on an oil rig can cost $750,000. Automobile

software errors can cost millions of dollars and loss of

customer satisfaction. The 2024 CrowdStrike

software error allegedly cost Delta Airlines $500 million. These errors are related to

documentation quality.

How the MAXit Six Sigma reporting works

The

MAXit Checker reads a technical document and gathers statistics. The statistics are based on

the number and type of errors in the

40 MAXit Error Classes that represent 19,000 AI rules.

A document can score one sigma (poor) to six sigma (excellent).

document is poor quality.

document is poor quality.  document is very-low quality.

document is very-low quality. document has too many defects.

document has too many defects. document needs editing, use MAXit.

document needs editing, use MAXit. good quality document, edit MAXit suggestions.

good quality document, edit MAXit suggestions. PERFECT

PERFECT

MAXit Checker Versions

Click a version to download (.pdf)

Data Sheet.

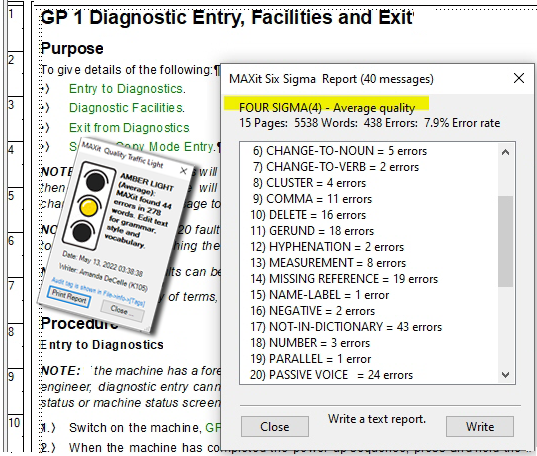

MAXit Six Sigma Report - No. 1

This screen shows a Six Sigma report for .xml FrameMaker document.

MAXit Traffic Light - report No. 2

A quick method to get an analysis is the MAXit Traffic Light.

A GREEN LIGHT means

the document has less than a 2% error rate.

An AMBER LIGHT means the text needs editing.

A RED LIGHT means the text is not acceptable.

The traffic light function adds

an audit trail that shows the writer a timestamp and six sigma score.

The acronym DIAMC indicates five

processes, Design, Improve, Analyze, Measure

and Control. The

writers use the MAXit Checker to control, correct and edit errors in software documentation.

For example, the cost of 1 hour of downtime on an oil rig can cost $750,000. Automobile

software errors can cost millions of dollars and loss of customer satisfaction. The 2024 CrowdStrike

software error allegedly cost Delta Airlines $500 million. These errors are related to documentation quality.

The acronym DIAMC indicates five

processes, Design, Improve, Analyze, Measure

and Control. The

writers use the MAXit Checker to control, correct and edit errors in software documentation.

For example, the cost of 1 hour of downtime on an oil rig can cost $750,000. Automobile

software errors can cost millions of dollars and loss of customer satisfaction. The 2024 CrowdStrike

software error allegedly cost Delta Airlines $500 million. These errors are related to documentation quality.

The MAXit Checker reads a technical document and gathers statistics. The statistics are based on

the number and type of errors in the 40 MAXit Error Classes that represent 19,000 AI rules.

A document can score one sigma (poor) to six sigma (excellent).

The MAXit Checker reads a technical document and gathers statistics. The statistics are based on

the number and type of errors in the 40 MAXit Error Classes that represent 19,000 AI rules.

A document can score one sigma (poor) to six sigma (excellent).

document is poor quality.

document is poor quality.  document is very-low quality.

document is very-low quality. document has too many defects.

document has too many defects. document needs editing, use MAXit.

document needs editing, use MAXit. good quality document, edit MAXit suggestions.

good quality document, edit MAXit suggestions. PERFECT

PERFECT